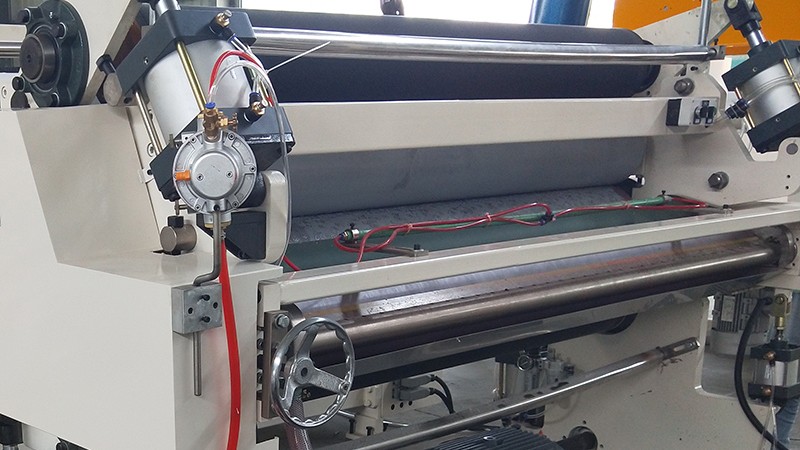

The glue treatment is carried out by a polyester film coated with hot melt adhesive, and the sealed article is bonded to the plastic film by the processing of the glue machine, since the processing is carried out under a certain pressure and high temperature, and the High-quality polyester film and hot-melt adhesive with good transparency, so that it can not only ensure that the molded articles are not damaged at room temperature, but also increase the visual effect of the articles. In this process, the technical performance of the glue machine is the key to ensure the quality of the plastic seal.

Roller glue machine product features:

- Roller glue machine is specially designed for large-area flat material sizing according to the product requirements and materials. The glue thickness can be adjusted. The environmentally friendly hot melt glue machine is used instead of self-adhesive glue and water-based glue.

- It has a safety design to prevent the hand from being caught in the roller and the anti-winding device to prevent the work object from being caught in the glue storage tank.Double pressure roller glue machine, pearl cotton glue machine, glue application machine, flat glue machine, glue machine, hot melt glue glue machine

- The main rotation system adopts stepless speed regulation, roller and glue tank independent temperature control, and double temperature protection rubber barrel adopts Teflon coating to greatly reduce the oxidation of the rubber and has reliable guarantee for product quality.

- The coating width can be selected from 200-1600MM according to different requirements of customers.

5. The use of brand motors, inverters, precision components are all manufactured by the imported CNC machining center.

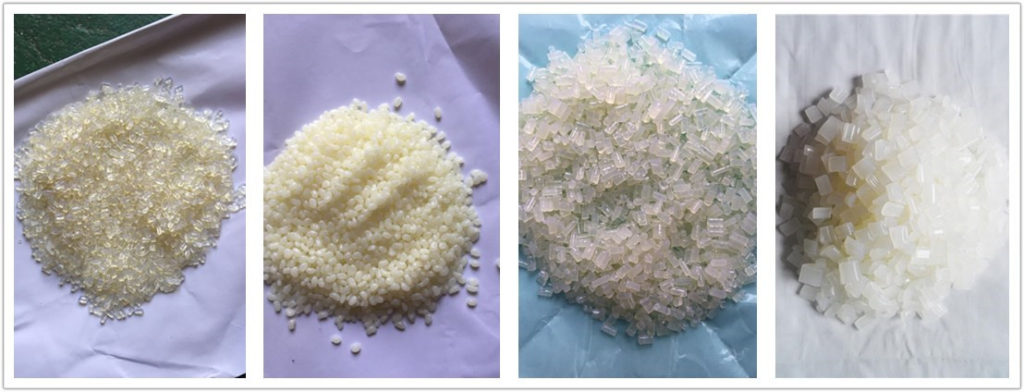

Hot melt adhesives are mainly used in the packaging industry, carpet composite, anti-slip, wet wipes cover, paper products, EVA sheets, aluminum masks, garment dressings, EPE pearl cotton packaging materials, non-woven composites and other industries.

Now It’s Your Turn

I hoped you enjoyed my detailed information for starting a business.

Now I want to hear from you:

Which parts from this post are you most excited to know ?

Are you going to know more other kinds of related products? Or do you want to do deep research on this line?

Let me know by leaving a quick comment.